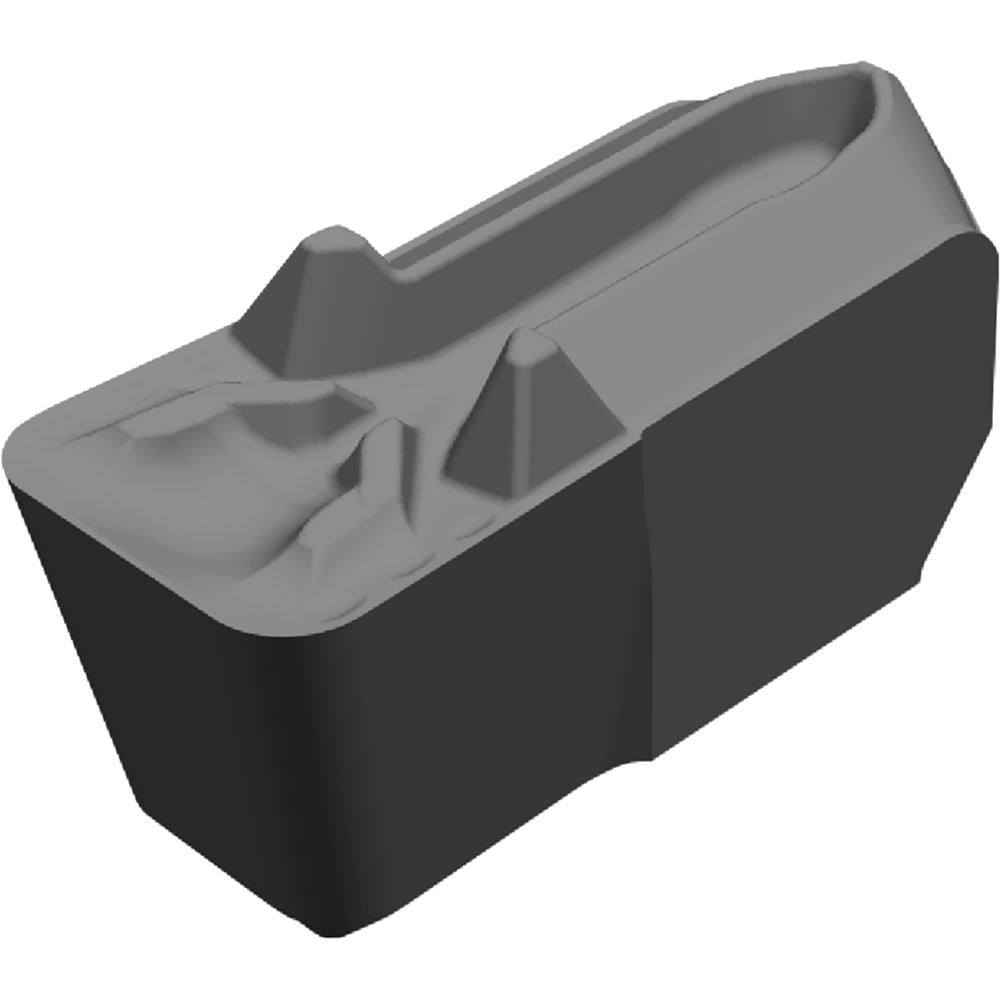

Grooving Inserts; Insert Style: WGC ; Insert Size Code: 3 ; Cutting Width (Decimal Inch): 0.125 ; Cutting Width (mm): 3.18 ; Insert Hand: Neutral ; Maximum Depth of Cut (Decimal Inch): 0.0882

Item Code: 17304924

Category

Grooving Inserts

Minimum quantity 5

Specifications

UNSPSC Code

23242105

ANSI Code

WG125I03P05PT

Brand

Undefined

Category

Grooving Inserts

Chip Breaker

PT

Coating Classification

PVD

Coating Process

PVD

Coating/Finish

TiAIN

Corner Radius (Decimal Inch)

0.0079

Corner Radius (mm)

0.20

Cutting Height (Decimal Inch)

0.0883

Cutting Height (mm)

2.24

Cutting Tool Application

Grooving

Cutting Width (Decimal Inch)

0.1250

Cutting Width (Inch)

1/8

Cutting Width (mm)

3.180

For Use With

Grooving

Full Radius

No

Groove Width (mm)

3.18

Hole Diameter (Decimal Inch)

0.0000

Hole Diameter (Mm) ( - 0 Decimals)

0.0000

Insert Hand

Neutral

Insert Height (Decimal Inch)

0.1578

Insert Holding Method

Clamp

Insert Material

Carbide

Insert Seat Size

3

Insert Size

3

Insert Size Code

3

Insert Style

WGC

Insert Thickness

4.01

Insert Thickness (Decimal Inch)

0.1578

ISO Code

WG125I03P05PT

Lead Angle

10.000

Manufacturer Grade

WU25PT

Manufacturers Catalog Number

WG125I03P05PT

Maximum Corner Radius (Decimal Inch)

0.0079

Maximum Depth of Cut (Decimal Inch)

0.0882

Maximum Depth of Cut (mm)

2.24

Maximum Groove Width (mm)

3.18

Minimum Groove Width (mm)

3.18

Minimum Insert Width (mm)

2.58

Multi-use Tool

No

Number Of Cutting Edges

1

Overall Length (Decimal Inch)

0.3761

Overall Length (mm)

9.5500

Overall Width (Decimal Inch - 4 Decimals)

0.1016

Primary Workpiece Material

Super-alloys & Titanium

Primary Workpiece Material Code

S

Rake

Positive

Relief Angle

10

Secondary Workpiece Material

Steel; Stainless Steel; Non-Ferrous Metal; Cast Iron

Secondary Workpiece Material Code

H; K; M; N; P

Series

WGC

Single or Double End

Single

Style

WGC Groove And Turn Insert

Type

WGC Groove And Turn Insert